IHR ONE-STOP-SHOP

FÜR MATERIAL HANDLING

Wagen für die Intralogistik, Postlogistik & Distributionslogistik

IHR ONE-STOP-SHOP

FÜR MATERIAL HANDLING

Wagen für die Intralogistik, Postlogistik & Distributionslogistik

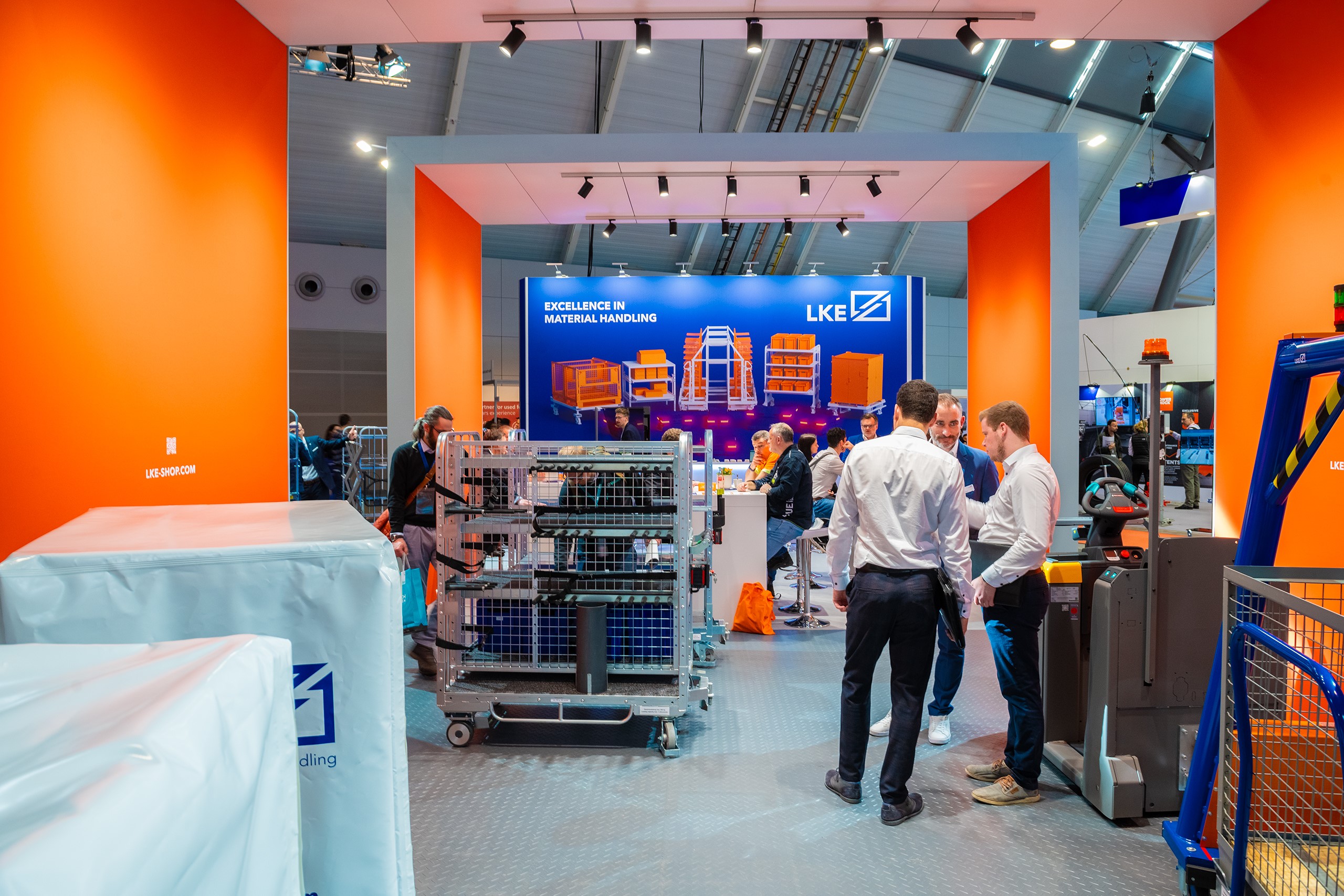

Excellence in Material Handling

LKE ist Ihr Ansprechpartner für einen effizienten und zuverlässigen Materialfluss in Ihrem Unternehmen. Durch unser großes Sortiment, fast endlose Kombinations- und Konfigurationsmöglichkeiten und kompetente Beratung finden wir die Lösung, die optimal auf Sie zugeschnitten ist.

Produkte

Jedes Transportgut hat seine Lösung. Und die Chancen stehen gut, dass sie bei LKE fündig werden. Transport von Paletten, Euroboxen, oder von Transportgeräten selbst. Lernen sie unser Produktsortiment kennen.

-

-

Cargo-Liner SP2

Art.-Nr: 566-1000-430-SP2 Cargo-Liner2 Stellplätze, Grundfläche 1780x750mm, Nutzfläche pro Stellplatz 430x638mm

-

-

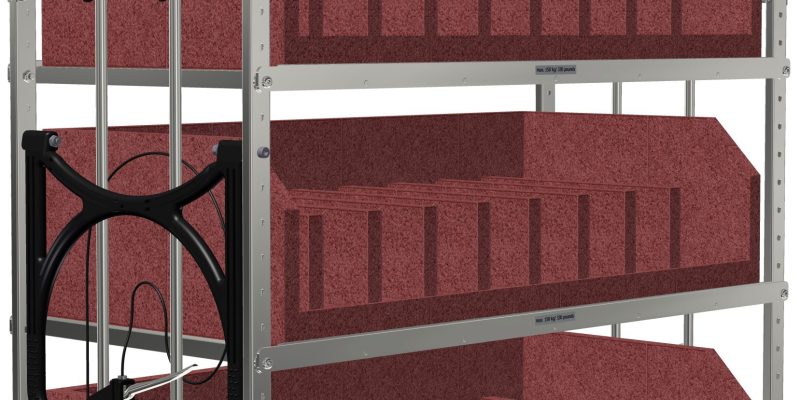

KLT-Wagen 600 E3 VKD ESD

Art.-Nr: 263-5712 EtagenwagenZuladung Grundboden 300kg, Zwischenböden mit Aufkantung 2x150kg, 2 Lenk- & 2 Bockrollen, zentraler Feststellhebel, Zuggriff, ESD-fähig über Lenk- und Bockrollen

-

-

-

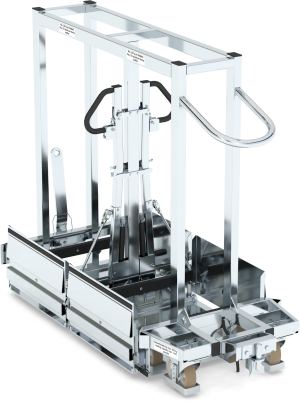

Plattformwagen Typ X.2 Euro VKD

Art.-Nr: 471-9002-A BodenrollerEuromaß, virtuelles Kupplungs-/ Deichselsystem

-

Schlepperdeichsel Linde/Still

Art.-Nr: SET-470-2100 Schlepperdeichselfür die Zugfahrzeuge Linde P30/P60 und Still R06

Zufriedene Kunden –

seit 1994

Wir blicken auf eine erfolgreiche Zusammenarbeit mit Unternehmen unterschiedlichster Branchen und Größen. Erfahren Sie in unseren Case Studies, wie Sie Ihren Materialfluss optimieren können.

LKE in den sozialen Medien

Unverbindliche

Produktberatung

Die erfahrenen Mitarbeiter unseres Customer Service Teams stehen Ihnen telefonisch oder per Mail zur Verfügung, um die optimale Lösung für Ihre Situation zu finden. Wir freuen uns auf Ihre Anfrage!